French Process vs Active ZnO Molecules

With the active zinc oxide products it offers, MELOS AŞ contributes significantly to reducing the zinc content in rubber products and to reducing the environmental damage of these products in both production and usage processes.

Zinc oxide (ZnO) in combination with stearic acid is considered an indispensable activator for sulfur vulcanization. It is traditionally used in concentrations of 3 or 5 phr. Zinc (Zn) can be released into the environment from rubber during the manufacture, use and recycling of rubber products, especially tires. Potential sources of zinc in groundwater are rubber powder eroded from tires and rubber granules produced from end-of-life tires used in the construction of artificial sports fields. According to the environmental directives of the European Union, zinc is classified as "Dangerous for the Environment" with the risk phrase "Very toxic to aquatic organisms, very toxic to aquatic organisms, may cause long-term adverse effects".

Studies on reducing the use of zinc oxide in rubber compounds continue on topics such as alternative vulcanization agents and more efficient use of zinc oxide.

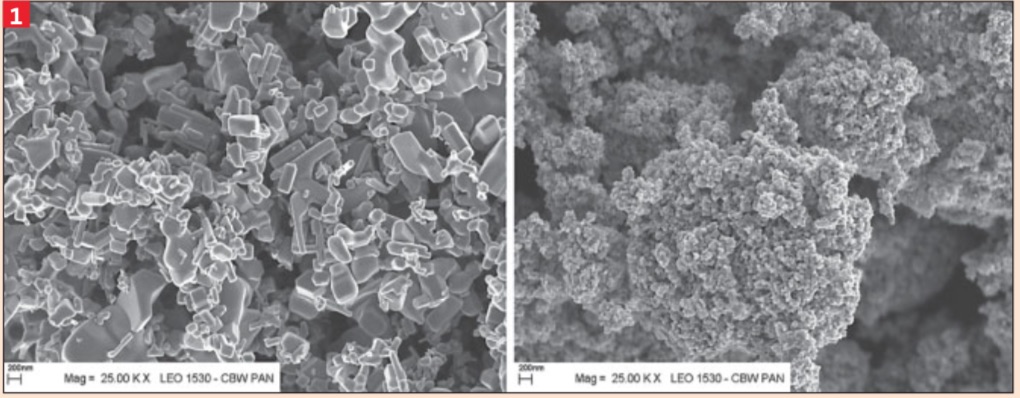

One of the possible ways to reduce the amount of zinc oxide in rubber compounds by almost half is to use Active Zinc Oxide products. MELOS AŞ produces Active Zinc Oxide products with fine particle size, high purity and most importantly, high surface area up to 70 gr / m2, with precise production processes. Since 2006, it has become one of the considerable manufacturers in our country and in the world with the production and quality control processes that it has continued to develop with its experience in the sector.

The multi-step chemical process, which starts with the selection of high purity raw materials, is strictly followed at each step, the proportions of all heavy metals, especially lead, in the final product are kept under control at a minimum and nano-level particle sizes are obtained thanks to high technology equipment. These molecules are easily and evenly distributed in the rubber compound thanks to their rounded structure and are much more effective than conventional zinc oxide products due to their surface area. Thus, up to 50 percent dosage savings can be achieved.

Since 2019, MELOS AŞ has made innovations that will highlight the ease of use in its new products. It has launched products containing controlled reduced zinc oxide, which can be used in place of traditional zinc oxide products, without the need to reduce the dosage and therefore change the formula, and which can be replaced at a 1: 1 ratio. Although these products contain less zinc oxide, they successfully provide all the desired mechanical and physical properties in the final product.

In addition to their positive contribution to the environment, these products also provide high economic benefits to the users. These products, which are produced by using less zinc metal by MELOS AŞ, allow to offer much more affordable prices than traditional zinc oxide products and final rubber products containing less zinc can be produced at more affordable prices.